Optimised Design for Production

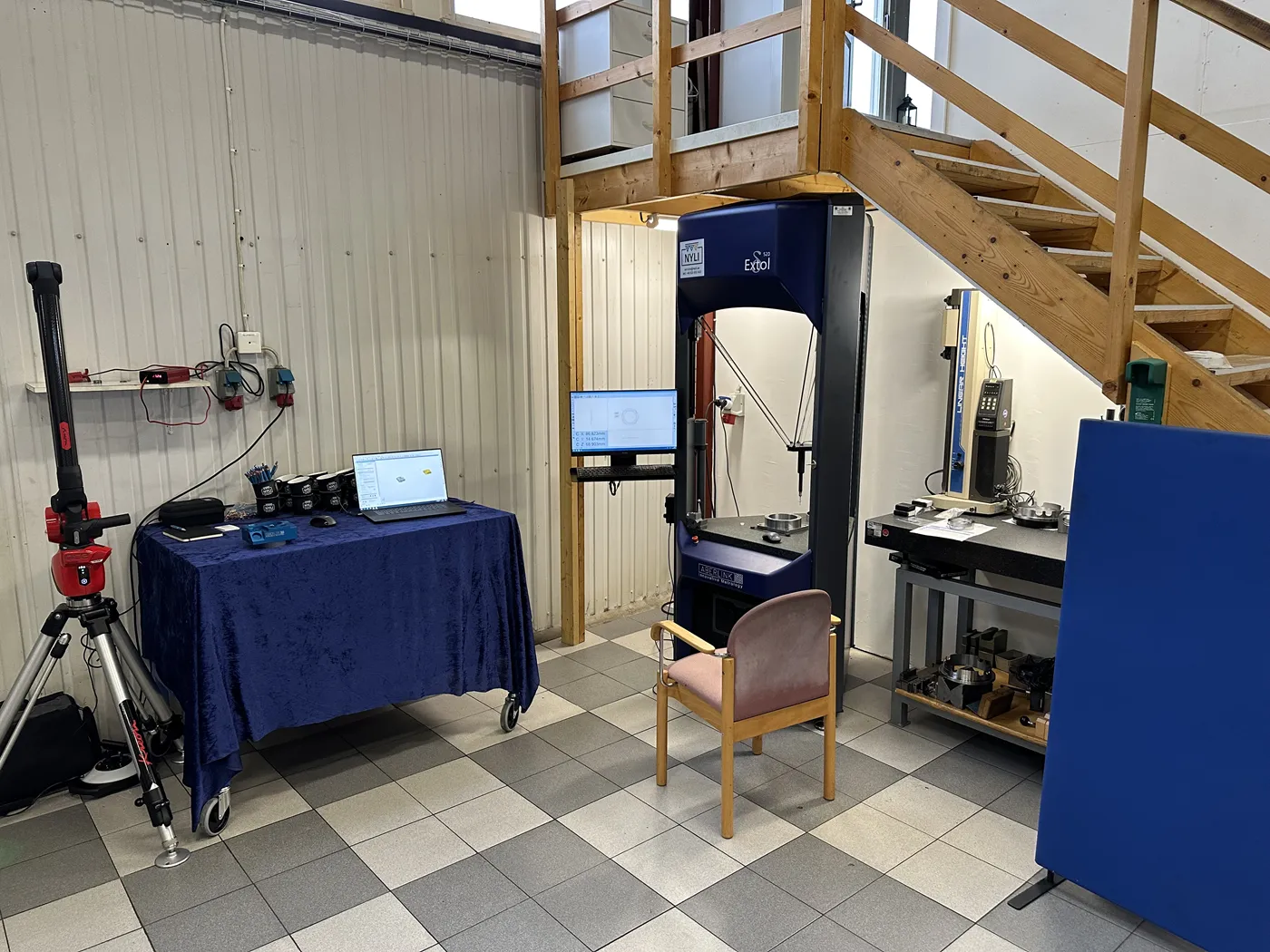

Automation

Aberlink 3D provides automatic deviation adjustment for machine tools, complementing Extol's robust design and making this measuring machine an obvious choice for automated production cells.

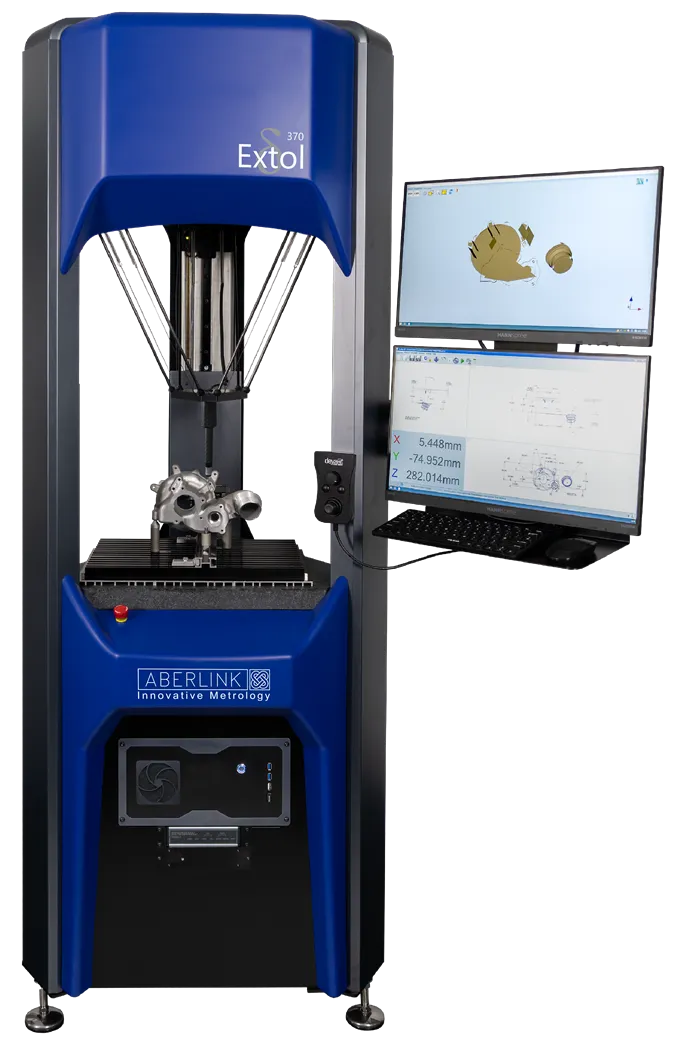

Optimal Design

Focus on ergonomics has marked Extol's design, where they have tried to maximise accessibility to the measuring area whether you have manual feeding or an automated robot cell for series production. With its compact design, it takes up minimal space on the production floor, making it flexible to place exactly where the need is greatest.

Tactile Scanning

Extol can now be delivered with the SP25M scanning module, scanning makes measurement fast for complex components. Smart integration and low profile in the SP25M mount make switching between scanning and triggering probe both quick and easy.