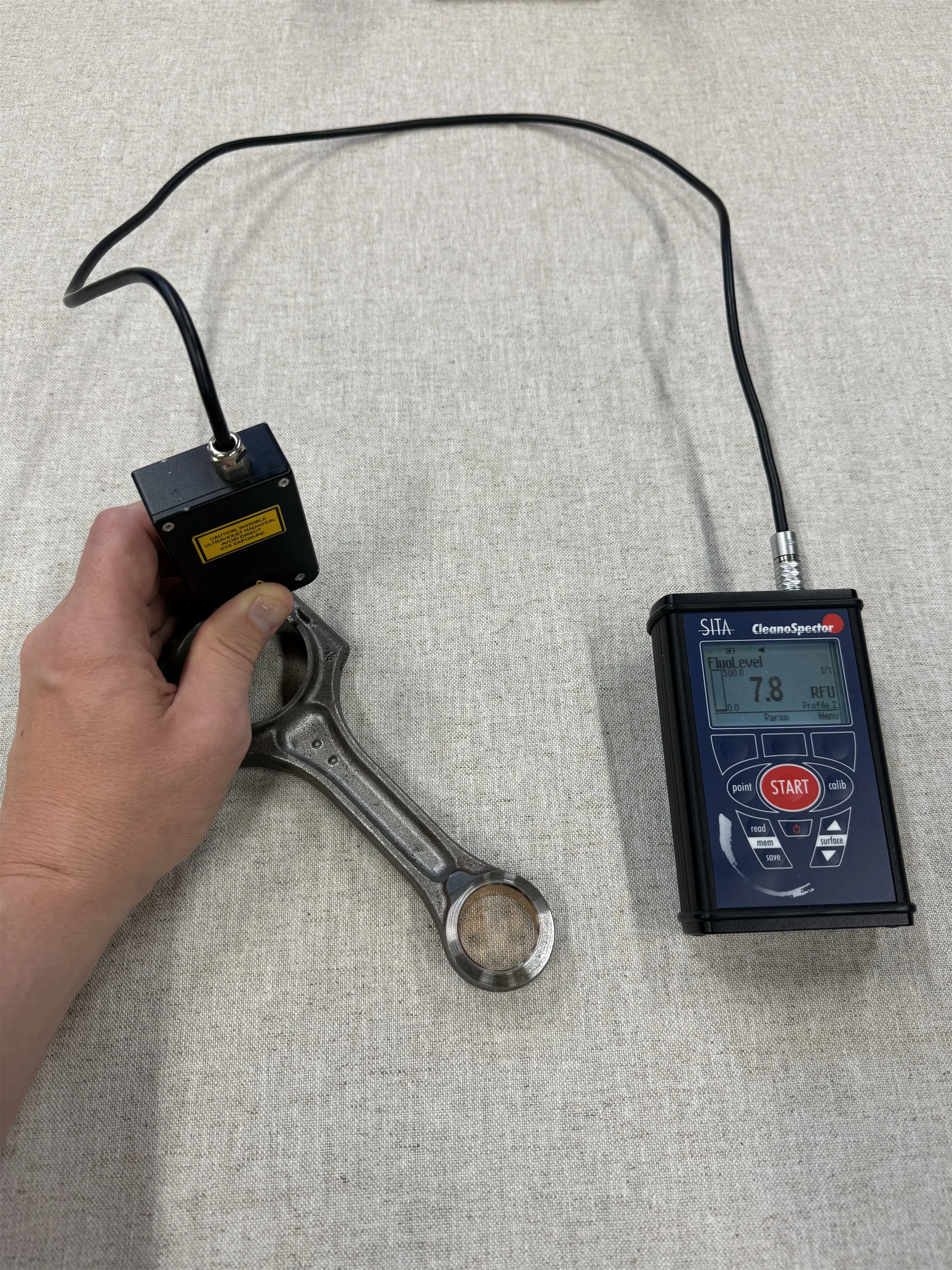

ConSpector

User-Friendly measurement with UV-fluorescence of bio-organic contamination in fluid such as oil, emulsion, fat and coolant fluid. Perfect for maintenance...

- User-Friendly

- Quick Measurements

- Compact portable design

The instrument use UV-light that interact with the filmic contaminations and create fluorescence which then is measured by a sensor.

Features:

Contact the Nyli-team to find the solutions that fit your needs!

User-Friendly measurement with UV-fluorescence of bio-organic contamination in fluid such as oil, emulsion, fat and coolant fluid. Perfect for maintenance...

User-Friendly instrument for surface tension in fluids which can be used to measure tenside concentration in cleaning bath.

User-Friendly contact angle measurement for verification of wettability before surface treatment on metall, plastic and glass.