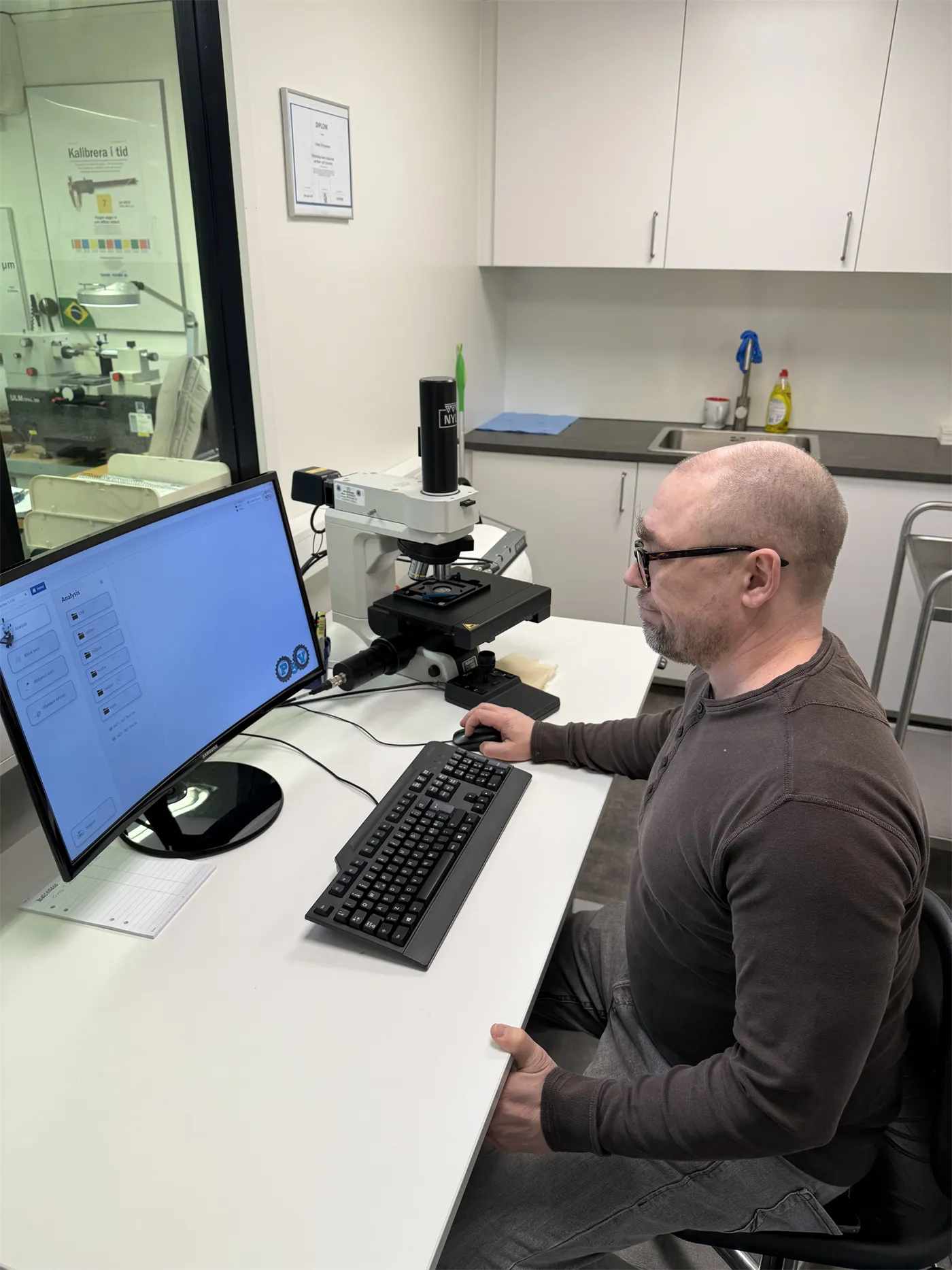

Cleanliness Cabinet CC-G4

Cleanliness cabinet for extraction of particles on manufactured components with cleanliness requirements conforming to: ISO 16232 , VDA 19.1 och ISO 4406...

- Controlled Enviroment for Particle Extraction

- Cirkular system filters and re-use the rinsing fluid

- Cascade filter mount as standard