Western Pegasus

Western Pegasus is a leading English manufacturer of splines, shafts, gears, measuring instruments and components for industrial applications. Through state-of-the-art technology, decades of experience, and certification within ISO 9001 and accreditation withinISO 17025, they ensure precision and quality at every step.

Spline ring and plug gauges

Western Pegasus offers a full line of spline ring and plug gauges that provide the most basic and simple inspection of spline components.

- Hand held or bench mounted

- Involute, serration or straight sided

- Spur or Helical

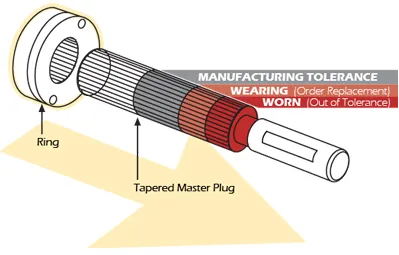

Tapered master plugs and wear indicating rings

Tapered master plugs (TMPs) are used for manufacturing and checking wear condition on ring gauges. A TMG has three lines inscribed as depicted in the diagram; a new ring is will be manufactured to fit between the first two lines. When the ring passes over the third line, the ring is worn.

When a TMG is used in the manufacture of new rings, it ensures that all new ring gauges are consistent in size and allow you to monitor ring wear simply and accuately. This is useful when multiple rings are supplied for use by subcontractors and end-users.

Variable indicating gauges and setting masters

Variable Gauging (Spline Variable) is a segmented concept that is pre-set to a master plug or ring gauge and is designed to accurately measure the effective or actual tooth thickness or space width within 0.0025 mm. The 0.001 mm resolution indicator clearly displays size due to heat treatment distortion, tool wear and manufacturing deviation.

Spline Variable options:

- Plug and ring type

- Composite (effective) and Sector (actual)

- Handheld or bench mounted

- Adaptable to leading statistical quality control systems (IE: Federal, Mitutoyo, Sigma ets)

Concentricity gauges

Concentricity gauges are used to assist in assuring that certain diameters are concentric or a face is square to the spline diameter.

The concentricity gauge is a segmented design with three spline rings, with two outer rings fixed and the central ring rotating to lock onto the component. To obtain a quantitative value, a dial gauge is set onto the concentricity band of the ring and the component is rotated.

Concentricity gauge options:

- Ring (for use between centres)

- Plug (for use between centres)

- Bench mounted gauge and ring type with fixed or positional indicators

Combo check

Ring – Indicates dimension over ball anvils

Gauge – Indicates dimension between ball anvils

The effective "Combo Check" gauge combines a go composite form with carbide pins/ball anvils (manufactured to the same diameter as component pins) that contact the part on a single plane providing dimension between/over the ball size.

The "Combo Check" gauge is pre-set on a master plug or ring and is used to measure the variation between or over pins or balls. Depending on the type of indicator used, the variation can be shown as eather an actual dimension between/over balls or the variation in increments of 0.0025 mm. To reduce the amount of rocking required for an accurate measurement, the tooth width form of the spline guide is manufactured above or below the minimal/maximum effective to reduce measurement bias due to misalignment.

The proprietary trigger mechanism on the plug type, fully retracts the pin anvils which not only increases accuracy and repeatability, but protects component parts as well.

Combo Check options:

- Plug and ring type configurations

- Handheld or bench mounted

- Composite or sector versions

- Adaptable to leading statistical quality control systems (Federal, Mitutoyo, Sigma, etc.)