Technical Cleanliness

Technical cleanliness involves identifying and managing particulate contamination that can negatively affect components, fluids, and systems. It is a crucial part of ensuring quality and operational reliability in many industries.

Technical Cleanliness – The Key to Quality and Operational Reliability

What Does Technical Cleanliness Include?

• Solid Particles: Measurable using methods such as particle counting and weight

measurement, often of metallic or organic nature.

• Surface Contaminants: Identified through tests like spraying or fluorescence, typically involving organic substances.

• Salts: Require specific methods for detection.

How to Improve Cleanliness?

• Major Measures:

• Invest in washing and analysis equipment.

• Optimize process design.

• Simpler Measures:

• Train personnel.

• Optimize planning and material selection.

• Maintain a clean working environment.

Our Solutions

We offer flexible systems and products tailored to customer needs.

• Particle Extraction: Performed through flushing cabinets that meet industry standards.

• Particle Analysis: Advanced methods ensuring precise results.

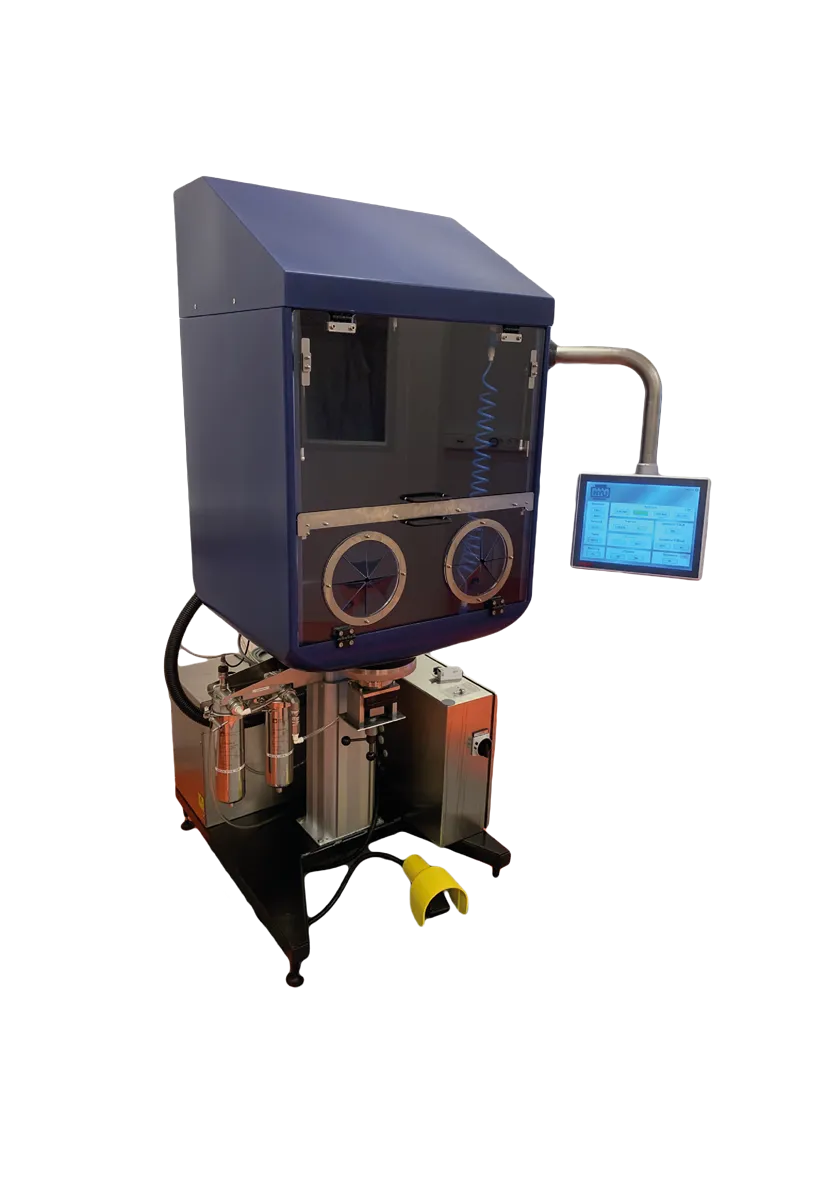

Flushing Cabinet CC G4 – Efficient and Adaptable

CC G4 is an ergonomic extraction cabinet for Technical Cleanliness, featuring a height-adjustable design and an integrated sink for optimal extraction.

Advantages:

• Cascade filters for efficient filtration (D47 and D90).

• Touchscreen control for managing flushing volume, pressure, and fluid quantity.

• Compatible with both alkaline fluids and solvents.

• Time-saving features and service reminders.

• Ergonomic design suitable for both right- and left-handed users.

CC G4 is a flexible solution for industries with high cleanliness requirements.

Contact us for more information!

Flushing Cabinet CC G4 – Efficient and Adaptable

CC G4 is an ergonomic extraction cabinet for Technical Cleanliness, featuring a height-adjustable design and an integrated sink for optimal extraction.

Advantages:

• Cascade filters for efficient filtration (D47 and D90).

• Touchscreen control for managing flushing volume, pressure, and fluid quantity.

• Compatible with both alkaline fluids and solvents.

• Time-saving features and service reminders.

• Ergonomic design suitable for both right- and left-handed users.

CC G4 is a flexible solution for industries with high cleanliness requirements. Contact us for more information!

ParticleView – Precisionsverktyg för Partikelanalys

ParticleView är ett analyssystem som kombinerar vår egenutvecklade mjukvara med högkvalitativa mikroskop för okulär räkning och storleksbestämning av partiklar. Systemet är utvecklat för att leverera hög precision och tillförlitlighet.

Fördelar med ParticleView:

• Avancerad teknik: Egen mjukvara optimerad för partikelanalys.

• Hög prestanda: Mikroskop noggrant monterade för bästa resultat.

• Framtidssäkrat: Uppdateras kontinuerligt för att möta standarder och kundspecifika krav.

Med vår expertis inom partikelanalys och avancerad teknik levererar vi produkter av högsta

kvalitet.

Kontakta Joakim för mer information!